Certified Welding Inspectors

Expert San Diego Welding Inspections

When it comes to ensuring the safety, strength, and compliance of welded structures, hiring an expert, certified welding inspector is essential. As experienced professionals based in San Diego, we provide certified welding inspections tailored to both construction and industrial projects. Whether you’re searching for a welding inspector near me or a Certified Welding Inspector (CWI) for your next build, we deliver reliable, code-compliant, and thorough inspection services across Southern California and beyond.

What Is Welding Inspection?

Our AWS-certified inspectors perform independent verification of weld quality, WPS compliance, and welder qualifications to help prevent defects, non-conformance, and avoidable rework.

Engaging a certified welding inspector early in the project lifecycle reduces downstream risk by ensuring welding procedures, materials, and workmanship conform to applicable codes and project specifications.

A Certified Welding Inspector (CWI) is qualified to assess weldments and welding procedures to ensure compliance with industry standards such as AWS D1.1, ASME, and other codes relevant to your project.

Why Hire a Certified Welding Inspector in San Diego?

The role of a CWI goes far beyond simply checking weld beads. Our certified professionals offer value on every project through:

✔ Code & Standard Compliance

Our inspectors are trained to evaluate welds against applicable codes and specifications, including AWS, ASME, API, and local building standards. This ensures your project meets both safety and regulatory requirements.

✔ Quality Assurance

Inspection is part of quality assurance (QA) and quality control (QC). We verify that welding procedures, welding equipment settings, and materials used are appropriate and documented correctly. This prevents costly rework due to non-compliance or defective welds.

✔ Material Verification

Quality weld inspection includes checking certification of base materials, filler metals, welder qualifications, and environmental factors that can affect weld quality.

✔ Contract & Project Support

Whether supporting the owner, contractor, or engineer, our inspectors act as a trusted third-party resource, delivering accurate documentation and actionable recommendations.

Our Welding Inspection Services

We provide a full range of inspection services designed to support construction, fabrication, and industrial operations:

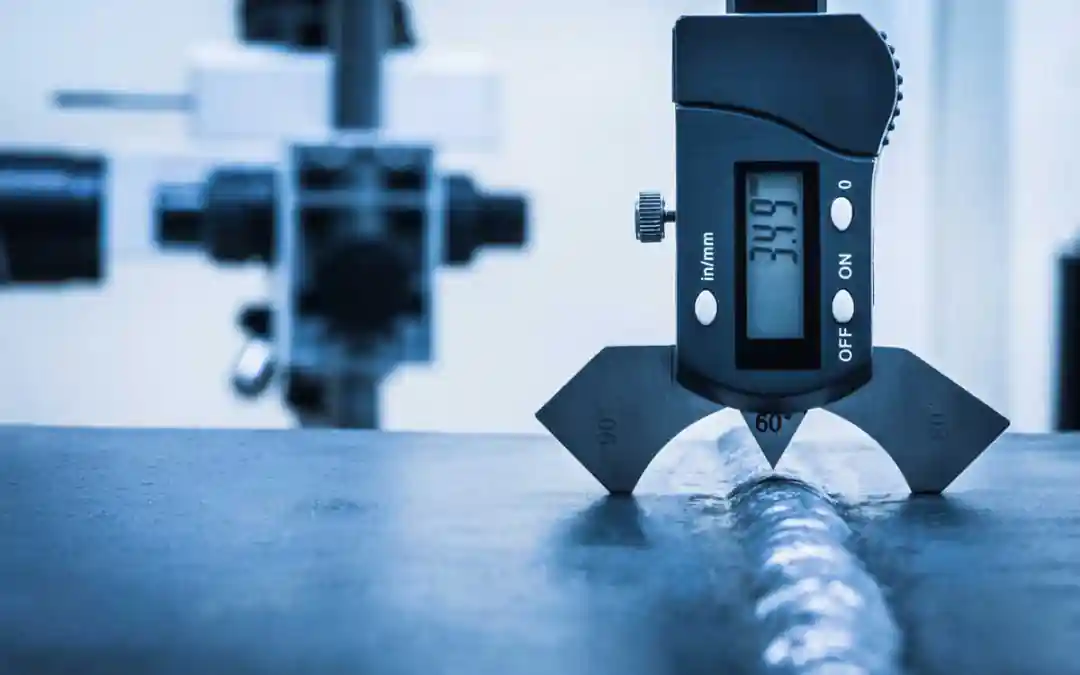

📌 Visual Weld Inspection (VT)

A Certified Welding Inspector performs comprehensive visual examinations of welds at every stage – from pre-fabrication, in-process to final completion. This includes identifying cracks, porosity, undercut, and other defects.

📌 Welder Qualification & Procedure Review

Before welding begins, our team reviews welding procedures (WPS/PQR) and welder qualifications to ensure they match project requirements and industry codes – a critical step in preventing non-compliant welds later.

📌 Quality Assurance & Control

We integrate with your quality assurance program or provide independent quality control oversight, ensuring that every weld is executed and documented to spec.

📌 Detailed Reporting

After inspection, we provide clear, professional reports that document findings, non-conformances, corrective actions, and compliance verification – delivered quickly to keep your project moving.

Industries We Serve with Welding Inspections

Our welding inspection services support a broad array of sectors, including:

- Commercial Construction

- Structural Steel Fabrication

- Industrial Facilities

- Infrastructure & Bridges

- Pipelines & Pressure Systems

- Marine & Shipbuilding

- Manufacturing & Fabrication

With AWS-certified CWI expertise and hands-on field experience, we ensure the integrity and longevity of welding work across all environments.

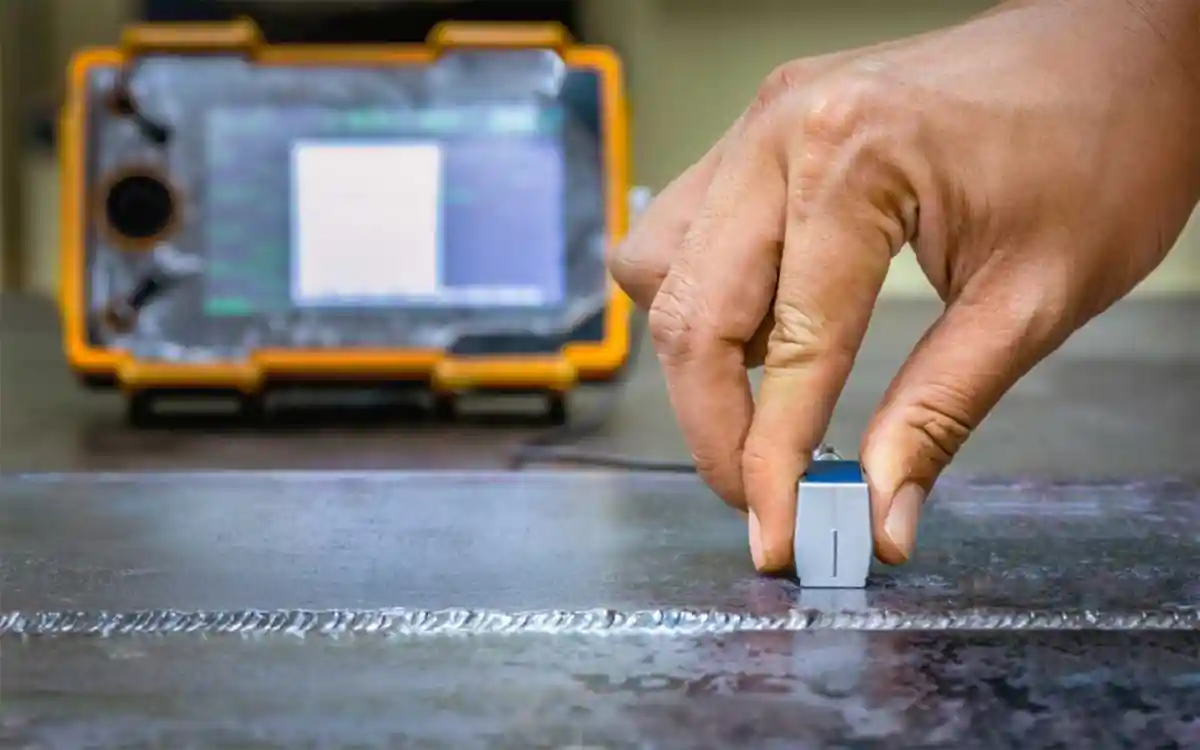

Pre-emptive Approach to Welding Inspection

Welding that does not conform to applicable codes or approved procedures can result in defective work, often requiring costly grinding, repair, and re-welding. As Certified Welding Inspectors, Metzger Testing & Inspection can assist contractors in avoiding after-the-fact issues by developing and verifying welding procedure specifications (WPS). Existing structures also require ongoing monitoring and evaluation to maximize service life, as structural issues may develop over time due to wear, corrosion, and applied stresses.

If a building owner observes excessive cracking or other signs of distress in an existing structure, call 619-889-1314. We can coordinate with a licensed structural engineer to evaluate load capacity, structural integrity, and provide the required engineering reports.

Why Choose Metzger Testing & Inspection?

⭐ Certified & Experienced

Our inspectors hold certifications from the American Welding Society (AWS), International Code Council (ICC), and comply with local building standards. This means you’re getting qualified professionals with proven expertise.

⭐ Proactive Problem Solving

We don’t just find issues — we work with contractors and owners to resolve weld quality concerns efficiently and help maintain project timelines.

⭐ Client-Focused Communication

Clear documentation, timely reporting, and responsive service ensure that stakeholders always stay informed and empowered to make decisions with confidence.